In today's hyper-aggressive international current market, manufacturers are frequently searching for means to boost effectiveness, reduce prices, and preserve the very best amounts of quality. regular methods of high-quality control tend to be time-consuming and at risk of human error. This is when eyesight measurement machine suppliers are stepping in with revolutionary methods which are revolutionizing producing procedures. This article will delve into how advanced vision measurement technological innovation, particularly specializing in Easson's reducing-edge 3-axis CMM machines, is not simply Conference present-day demands, but actively foreseeable future-proofing all the producing sector.

Table of contents:

AI Integration and Automation: The Next Frontier in Measurement

true-Time details Assessment: reducing Downtime, Maximizing Output

Easson’s 3-Axis CMM: top the Charge in Scalability and Adaptability

AI Integration and Automation: the subsequent Frontier in Measurement

The mixing of Artificial Intelligence (AI) and automation is no more a futuristic idea; it’s a existing-working day truth dramatically enhancing the capabilities of your vision measurement device. AI algorithms empower these machines to master from large datasets, autonomously enhance measurement parameters, and detect even one of the most delicate defects with unparalleled pace and accuracy. This translates to a substantial reduction in human intervention, minimizing the risk of mistakes and accelerating inspection periods. Automated managing systems even further streamline functions by seamlessly incorporating measurement procedures into the present production line, causing a hugely productive and optimized workflow. The improved throughput allows producers to satisfy demanding manufacturing schedules devoid of compromising high quality.

Real-Time info Assessment: reducing Downtime, Maximizing Output

authentic-time information Assessment is proving being a pivotal Instrument for suppliers striving to minimize costly production downtime. modern day vision measurement methods at the moment are Geared up with sturdy computer software platforms capable of delivering speedy and actionable feed-back on essential Proportions, tolerances, and approach versions. This instantaneous information stream allows proactive identification of likely problems, which include untimely Instrument don, machine calibration deviations, or substance inconsistencies, prolonged right before they escalate into significant defects or catastrophic production stoppages. By leveraging this real-time intelligence, makers can put into practice quick corrective steps, enhance approach parameters, and in the long run ensure constant, uninterrupted production though reducing wasted assets and scrap substance.

Easson’s three-Axis CMM: Leading the demand in Scalability and Adaptability

Easson's three-axis CMM (Coordinate Measuring device) machines are on the vanguard of vision measurement engineering, offering unparalleled scalability and adaptability to meet the evolving demands of modern producing. These devices are meticulously engineered to support a diverse range of part sizes, complicated geometries, and various product kinds, earning them ideally fitted to a broad spectrum of producing apps, from aerospace to automotive. As comprehensive on https://zh-easson.com/products/visual-video-cmm-measurement-machine-with-3-axis-001%CE%BCm-linear-encoder, Easson's devices are renowned for his or her Outstanding accuracy, boasting remarkable 0.001μm linear encoders, check here guaranteeing the best doable amount of precision and repeatability. Their modular design and style facilitates seamless updates and customizations, letting brands to adapt quickly to shifting production necessities and technological developments without incurring significant capital expenditure. Moreover, Easson's unwavering motivation to person-welcoming software package interfaces and detailed education applications makes sure a seamless integration method and exceptional utilization in their advanced technologies, empowering operators To optimize the equipment’s opportunity.

In conclusion, vision measurement technological know-how signifies far more than just a complicated high quality Regulate Resource; It is just a strategic very important for suppliers trying to get to foreseeable future-evidence their operations and keep a competitive edge in today's demanding market. By embracing the strength of AI integration, actual-time information Assessment, and really scalable options like Easson's Sophisticated 3-axis CMM machines, producers can reach unparalleled levels of precision, considerably decrease downtime, optimize production performance, and eventually generate considerable enhancements in profitability. The strategic expenditure With this transformative technologies just isn't just a choice but a necessity for prolonged-phrase results. go ahead and take proactive phase to explore how advanced vision measurement remedies can empower your company to thrive in the at any time-evolving production landscape, and access out to a reliable eyesight measurement equipment supplier to debate your certain demands and prerequisites now.

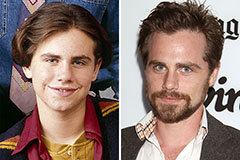

Rider Strong Then & Now!

Rider Strong Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now!